Separlab

Hledat

Gradient forming devices

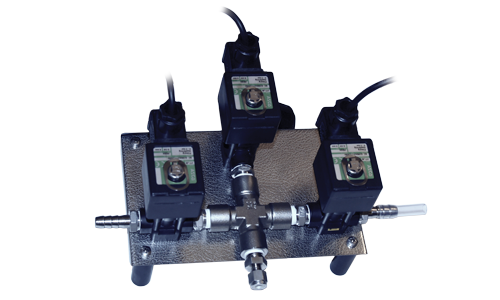

Separmix V

GRADIENT VALVES

Separmix V is a series of gradient valves different sizes for low pressure gradient forming. They are designed to be controlled either from a pump Separtrix PP03 (G) or from a single programming unit Separmix PX. Special solenoid valves can be used for the control of even aggressive liquids in the pharmaceutical, chemical and biochemical industries. Valves suited for all applications in which the fluids must not come into contact with the magnetic metal kern of the solenoid valve are available as an option. Each set of valves is completed by manifolds on the input and output to allow the connection to the liquid reservoirs on one side and to the chromatography pump on the opposite side. The manifold with valves is situated on a stainless steel plate. Plates are equipped either with legs, or can be connested directly to the pump PP03 from its left side.

There are three dimensions of gradient mixer valves sets depending on maximal flow rate. Maximum liquid viscosity to be used with mentioned valves systems is 40 cSt (mm2/s) and temperature range -10 °C to +90 °C. Material in contact with fluid are: stainless steel, PTFE and UHMWPE. Maximal input pressure is 2 bars

Separmix P

PROGRAMMING UNITS

Separmix P is a low pressure gradient programming unit situated in a stainless steel box with graphic display and membrane keyboard on oblique front panel. It is used in combination with a set of solenoid valves Separmix V to form a low pressure gradient of mobile phase on the pump input. Gradient program consist of 10 linear steps for two or three liquids. Programming unit SEPARMIX is connected by cable to each gradient valve. Remote control of the instrument is possible.